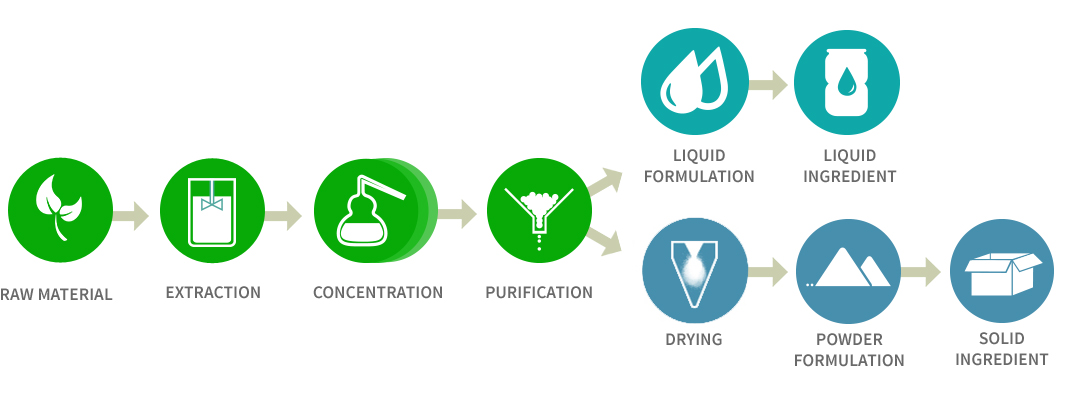

From nature to application

Uncovering the benefits of nature with innovative technologies

Our core business is built upon our ability to control the technologies used for extraction, purification, and liquid and powder formulation. Naturex is known for its large industrial capacity and expertise. Over the years, we have diversified our technologies by pooling and adapting equipment and methods from our various acquisitions. Through open dialogue between our production sites and the exchange of technological knowledge, our industrial performance continues to advance on a daily basis.

Extraction: infusion on an industrial scale

The process of extraction isolates and extracts the major active principles and properties of the plant. After harvesting, drying, and grinding, the plants are immersed in a solvent that demonstrates an affinity with the molecules being extracted. Numerous factors affect the performance and selectivity of the extraction: managing timing, setting the temperature, adjusting the pressure, choosing the solvent. A filtration system separates the solvent and desired compounds from the plant structure. The solvent is then evaporated at low temperature in order to concentrate the active compounds. The resulting crude extract is then purified and may be used as is or formulated to meet specific requirements.